Professional Design M8 T Nut - Hexagon Nuts With Metric Coarse And Fine Pitch thread M1-M160 grade 4 with white zinc plated surface – Tiancong Detail:

Surface treatment

We have our own surface treatment plant, and the thickness of zinc layer meets the standard requirements. We can make authoritative inspection reports, including surface treatment such as hot galvanizing, Dacromet, electro galvanizing, boiling black, etc.

The outer hexagon screw is a matching nut used to fasten and connect two connected parts with through holes and components. Hex head screws are commonly used bolts. It is more important to use Class A and Class B outer hexagon. In addition, it is often used in the occasion of high assembly accuracy, large impact, vibration or cross rate load. Grade C outer 66 screws are used in situations where the surface is rough and the assembly accuracy is not required.

Product standards

GB series, Q standard series, DIN German standard series, IFI American standard series, BS British standard series, JIS Japanese standard series, ISO international standard series, etc.

One of the standards for hexagon bolts is the level standard, which is divided into 4.8 and 8.8. These two levels are used more frequently in the market. Especially Grade 4.8 outer hexagon bolt. Because it is much cheaper than grade 8.8 hex bolts. Of course, it is more widely used. But for products with high requirements. Because of its high requirements in hardness and other aspects.

Material

The material comes from a high-quality steel manufacturer, which can issue an authoritative material inspection report, including Q235, 35 #, 45 #, 345B, 40Cr, 35CrmoA, stainless steel 201, 304 and other special materials.

This requires the use of grade 8.8 hex bolts. Grade 8.8 outer hexagon bolt is harder in terms of hardness and screw torque. It is safer to use the product. Faster and more stable.

Exported countries or regions

Poland, Russia, Algeria, Egypt, Ghana, Kuwait, the United Arab Emirates, Kazakhstan, Malaysia, Pakistan, the Philippines, South Korea, Myanmar, Thailand, Ukraine, Syria, India, the United States, Turkey, Brazil, Sri Lanka, Norway, etc.

Product Parameters

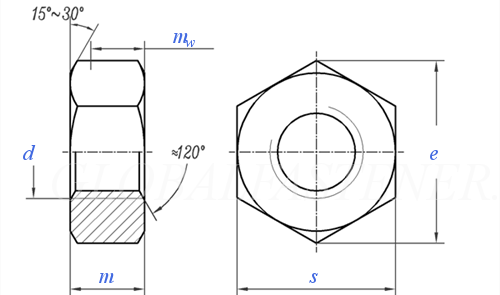

| Thread Size d | M4 | M5 | M6 | (M7) | M8 | M10 | M12 | (M14) | M16 | (M18) | M20 | (M22) | M24 | (M27) | M30 | (M33) | |||

| P | Pitch | Coarse thread | 0.7 | 0.8 | 1 | 1 | 1.25 | 1.5 | 1.75 | 2 | 2 | 2.5 | 2.5 | 2.5 | 3 | 3 | 3.5 | 3.5 | |

| Fine thread-1 | / | / | / | / | 1 | 1 | 1.5 | 1.5 | 1.5 | 1.5 | 2 | 1.5 | 2 | 2 | 2 | 2 | |||

| Fine thread-2 | / | / | / | / | / | 1.25 | 1.25 | / | / | 2 | 1.5 | 2 | / | / | / | / | |||

| m | max=nominal size | 3.2 | 4 | 5 | 5.5 | 6.5 | 8 | 10 | 11 | 13 | 15 | 16 | 18 | 19 | 22 | 24 | 26 | ||

| min | 2.9 | 3.7 | 4.7 | 5.2 | 6.14 | 7.64 | 9.64 | 10.3 | 12.3 | 14.3 | 14.9 | 16.9 | 17.7 | 20.7 | 22.7 | 24.7 | |||

| mw | min | 2.32 | 2.96 | 3.76 | 4.16 | 4.91 | 6.11 | 7.71 | 8.24 | 9.84 | 11.44 | 11.92 | 13.52 | 14.16 | 16.56 | 18.16 | 19.76 | ||

| s | max=nominal size | 7 | 8 | 10 | 11 | 13 | 17 | 19 | 22 | 24 | 27 | 30 | 32 | 36 | 41 | 46 | 50 | ||

| min | 6.78 | 7.78 | 9.78 | 10.73 | 12.73 | 16.73 | 18.67 | 21.67 | 23.67 | 26.16 | 29.16 | 31 | 35 | 40 | 45 | 49 | |||

| e ① | min | 7.66 | 8.79 | 11.05 | 12.12 | 14.38 | 18.9 | 21.1 | 24.49 | 26.75 | 29.56 | 32.95 | 35.03 | 39.55 | 45.2 | 50.85 | 55.37 | ||

| * | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | |||

| per 1000 units ≈ kg | 0.81 | 1.23 | 2.5 | 3.12 | 5.2 | 11.6 | 17.3 | 25 | 33.3 | 49.4 | 64.4 | 79 | 110 | 165 | 223 | 288 | |||

| Thread Size d | M36 | (M39) | M42 | (M45) | M48 | (M52) | M56 | (M60) | M64 | (M68) | M72 | (M76) | M80 | (M85) | M90 | M100 | |||

| P | Pitch | Coarse thread | 4 | 4 | 4.5 | 4.5 | 5 | 5 | 5.5 | 5.5 | 6 | 6 | / | / | / | / | / | / | |

| Fine thread-1 | 3 | 3 | 3 | 3 | 3 | 3 | 4 | 4 | 4 | / | 6 | 6 | 6 | 6 | 6 | 6 | |||

| Fine thread-2 | / | / | / | / | / | / | / | / | / | 4 | 4 | 4 | 4 | 4 | 4 | 4 | |||

| m | max=nominal size | 29 | 31 | 34 | 36 | 38 | 42 | 45 | 48 | 51 | 54 | 58 | 61 | 64 | 68 | 72 | 80 | ||

| min | 27.4 | 29.4 | 32.4 | 34.4 | 36.4 | 40.4 | 43.4 | 46.4 | 49.1 | 52.1 | 56.1 | 59.1 | 62.1 | 66.1 | 70.1 | 78.1 | |||

| mw | min | 21.92 | 23.52 | 25.9 | 27.5 | 29.1 | 32.3 | 34.7 | 37.1 | 39.3 | 41.7 | 44.9 | 47.3 | 49.7 | 52.9 | 56.1 | 62.5 | ||

| s | max=nominal size | 55 | 60 | 65 | 70 | 75 | 80 | 85 | 90 | 95 | 100 | 105 | 110 | 115 | 120 | 130 | 145 | ||

| min | 53.8 | 58.8 | 63.1 | 68.1 | 73.1 | 78.1 | 82.8 | 87.8 | 92.8 | 97.8 | 102.8 | 107.8 | 112.8 | 117.8 | 127.5 | 142.5 | |||

| e ① | min | 60.79 | 66.44 | 71.3 | 76.95 | 82.6 | 88.25 | 93.56 | 99.21 | 104.86 | 110.51 | 116.16 | 121.81 | 127.46 | 133.11 | 144.08 | 161.02 | ||

| * | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | |||

| per 1000 units ≈ kg | 393 | 502 | 652 | 800 | 977 | 1220 | 1420 | 1690 | 1980 | 2300 | 2670 | 3040 | 3440 | 3930 | 4930 | 6820 | |||

Why choose Us

Based on products with high quality, competitive price, and our full range service, we have accumulated professional strength and experience, and we have built up a very good reputation in the field. Along with the continuous development, we commit ourselves not only to the Chinese domestic business but also the international market. May you moved by our high quality products and passionate service. Let’s open a new chapter of mutual benefit and double win.

Product detail pictures:

Related Product Guide:

It can be a great way to enhance our solutions and service. Our mission would be to build inventive products to consumers with a superior working experience for Professional Design M8 T Nut - Hexagon Nuts With Metric Coarse And Fine Pitch thread M1-M160 grade 4 with white zinc plated surface – Tiancong, The product will supply to all over the world, such as: Niger, Florence, Juventus, Taking the core concept of "to be the Responsible". We will redound up on society for high quality products and good service. We will initiative to participate in international competition to be a first- class manufacturer of this product in the world.

We have been appreciated the Chinese manufacturing, this time also did not let us disappoint,good job!

-

Chinese Professional Wing Nuts With Washer Base...

-

2022 Latest Design 5 Inch Hex Bolt - Factory D...

-

Online Exporter Hex Bolts For Wood - Factory D...

-

Bottom price Steel Hex Screws - Cross groove s...

-

Wholesale Discount Removing A Rounded Hex Bolt ...

-

18 Years Factory Round Screw - Cross sink self...